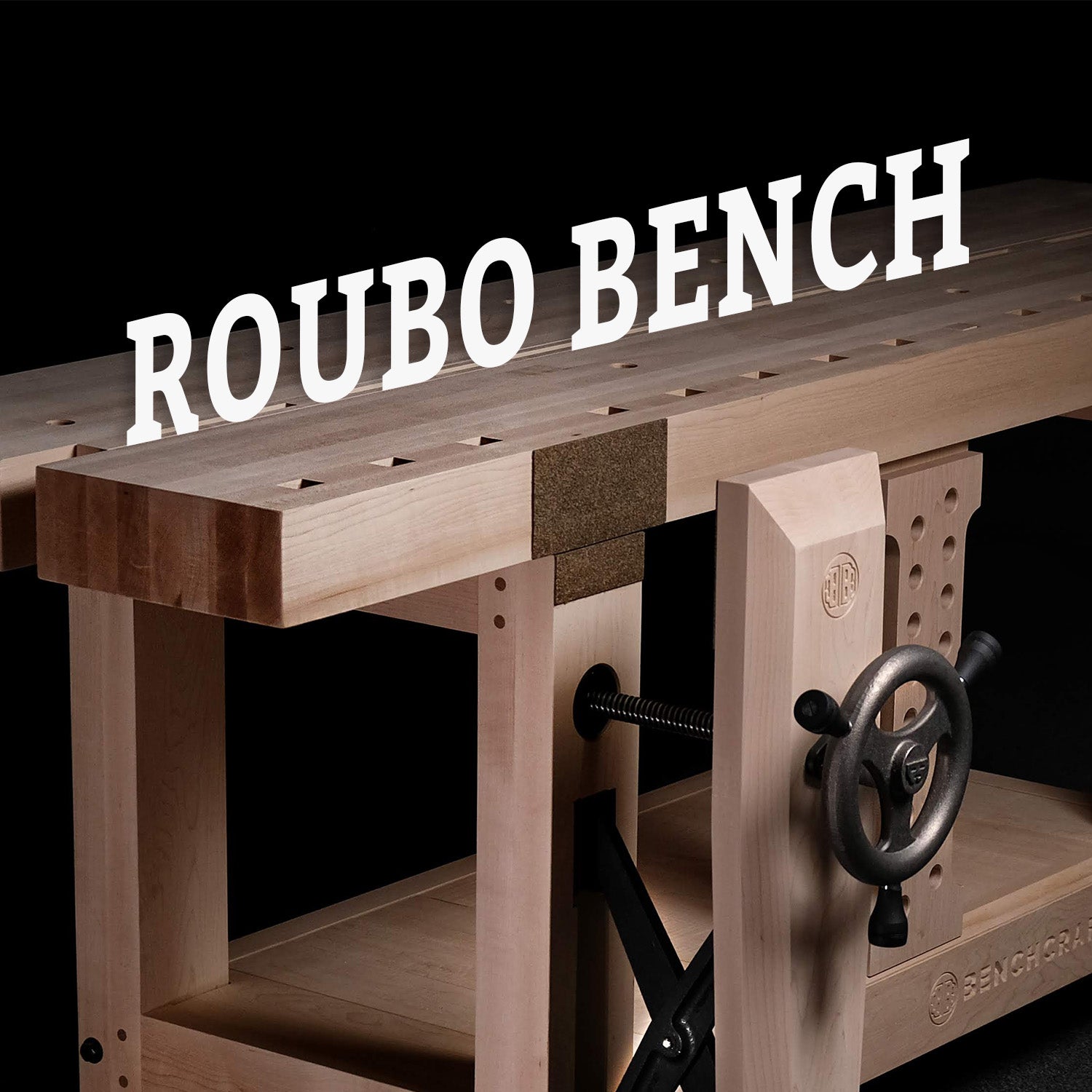

Split Top Roubo Bench

Vises

The STR excels at holding work in the three most necessary positions: for working the edges, faces, and ends of boards.

The Glide Leg Vise, used primarily for working edges, functions without thought. Simply spin the massive cast iron handwheel and allow the chop to close against the workpiece. In most cases no further tightening is required. For working long boards on edge the sliding deadman comes into play providing vertical support for the opposite end of the board via a peg placed in the deadman. Holes in the front right leg also allow the attachment of a batten via holdfast for supporting even longer boards.

The Tail Vise is ideal for working the faces of boards with work held between wooden dogs. You can do mallet work without worry while using the Tail Vise, since the vise's design maintains the robust structure of the top surrounding the vise. You can work the ends of boards in the Tail Vise jaw, but we prefer and recommend our Moxon Vise for dovetailing. The first dog is positioned directly over the leg, and allows clamping of very short pieces. This is handy for holding narrow boards across their width for certain tasks. An access hole in the leg allows the first dog to be pushed up easily. Every bench is provided with three dogs.

Gap Stop

The Gap Stop runs down the middle of the bench between the two top sections and features a slot for storing tools.

The bottom of the Gap Stop rests on the upper short rails of the end sections and when pushed towards the end of the bench raises up 1/2" via ramped sections milled into the bottom of the Gap Stop. The stop is excellent for working boards across their width. Remove the Gap Stop entirely by simply lifting it away from the bench to clamp work directly to the top between the top sections.

1" holes are strategically placed throughout each top section for Crucible holdfasts (available separately)

Gap Stop Up

Gap Stop Down

Knockdown Design

The two end sections are joined with drawbored mortise and tenon. Each end section joins to the long rails with four Benchcrafted Barrel Nuts. This allows the base to break down for easier moving. The tops register onto the base on four massive tenons at the top of each leg and are held securely to the base with four Spax lag screws.

Construction

The Split Top Roubo is constructed with massive components in American hard maple (acer saccharum). The tops are made by laminating 8/4 stock on edge for stability, yielding tops 4" thick by 87" long. The legs are 3-1/2" thick by 5-3/8" wide with the remaining base elements 3" thick and 1-3/4" thick. The 3/4" shelf boards rest on ledger strips fastened to the rails, and are easily removed for transport or cleaning. The complete bench weighs upwards of 350 pounds. It does not move under the most rigorous woodworking activities.

S4S Kit

Our Split Top Roubo S4S Kit greatly reduces the time and effort needed to build your Split Top Roubo workbench, but still gives you the satisfaction of building your own bench. We prepare each component in the same way as when we build our complete workbenches, then you cut all the joinery and install the vises.

The kit comes with everything you need to build our Split Top Roubo bench including wood and vise hardware.

Milled from select and better white hard maple, each component is surfaced on four sides to precise accuracy, but left slightly oversized in certain dimensions for further refinement and joinery processes.

The legs, vise chop, and two top sections are laminated from 8/4 stock. The rest of the components are milled from single boards

Specifications

Designed and made in the USA

87 inches

24 inches

35 inches

4 inches

350+ pounds

North American Rock Maple (Acer Saccharum)

None. Benches supplied in-the-white, ready to use.

Glide or Classic Leg Vise

Matching Tail Vise

Instructions

Installation instructions for all our products are supplied only in PDF format. Please download and review the instructions before using your product.

Similar Products