F.A.Q.

Frequently Asked Questions

General Vise Info

Do I need to lubricate the vises?

Yes, but very sparingly. Only use lubrication when a thorough cleaning and a check for interference with wood components have not yielded smooth movement.. We clean our vises at our shop about once a year with a blast of compressed air in the nut threads and along the screw, followed by a very light application of lubricant, usually a dry type lube, such as that used for bicycle chains. Don't use grease, thick oils, or paste wax on the moving parts of the vise. Those products will attract dust and make things worse. Our screws are precision rolled, and thus very smooth and polished. They don't need much lubrication to work smoothly. Keeping them clean is the most important "lubricant" you can use.

Won't the unpainted parts of the vise rust? How do I preserve the look of the vises out of the box?

Yes of course, just like any steel tool in your shop. Treat the vises as you would a table saw top, jointer beds or cast iron hand planes. In other words, keep moisture away, and keep surfaces waxed or oiled. You don't need much. We keep our shop climate controlled, but we don't go crazy with it. Just keep it warm enough that condensate doesn't get a chance to form. The cast iron handwheels will, over time and use, develop a wonderful rich brown patina from skin oils, like those seen on old machinery or old iron hand planes.

If you'd like to treat your wheels to prevent this, or to prevent rust, you can apply a boiled linseed oil finish to the wheels, or Tru-oil. This will protect them from moisture and maintain their look for a longer period. It will wear off with use though. We recommend keeping them natural and letting a patina form. If you want to freshen up the rim of the wheel spin it around with one hand and with the other hold maroon or gray Scotch-Brite against the surface. Follow links below for more info on finishing options.

Cold Bluing HandwheelsBaked

What about the pores and surface irregularities on my vise?

Our handwheels are made in the heartland of America from cast gray iron. Due to the nature of the sand casting process, there may be some porosity and irregularities visible in the surfaces of the handwheels. We reject castings with glaring or functional defects, but many small marks we not only allow to pass quality control, we actually like to see a bit of in our castings. Quite a bit of human effort, machine time, natural resources, and energy go into each handwheel we make. Although we're not tree-huggers, we do feel that unwarranted disregard for these factors would be irresponsible on our part. We're also not snobs about needing everything to be perfect. We like patina and slight distress. That's why we now run every handwheel through a vibratory finishing process to ease edges and take the sharp areas down to a more tactile level. The result is a handwheel with just enough character to look almost like a hand-forged piece. This look fits perfectly with the aesthetic of the classic woodworking benches our vises were designed around.

Do you have any videos showing how to install the Vise?

Our European dealer Dieter Schmid Fine Tools has prepared this basic video showing how to install the Glide Leg Vise. It also covers the installation of the Crisscross Solo and Retro, and the same installation process applies to the Classic Leg Vise as well.

Leg & Tail Vise

When I try to assemble the handwheel/hub to the screw, the groove pin doesn't stay in place.

We can send you a replacement pin, but the best solution is to simply put the pin in a vise about half way, then tap the exposed end with a hammer a couple times to put a slight bend in the pin. Easy now, just a slight bend! Before driving the pin in finally, add a couple drops of Loctite to keep it in place. This will keep the pin in place when you reassemble the handwheel.

What if I can only purchase one vise right now, which one should I get?

The short answer is the Tail Vise. Read more

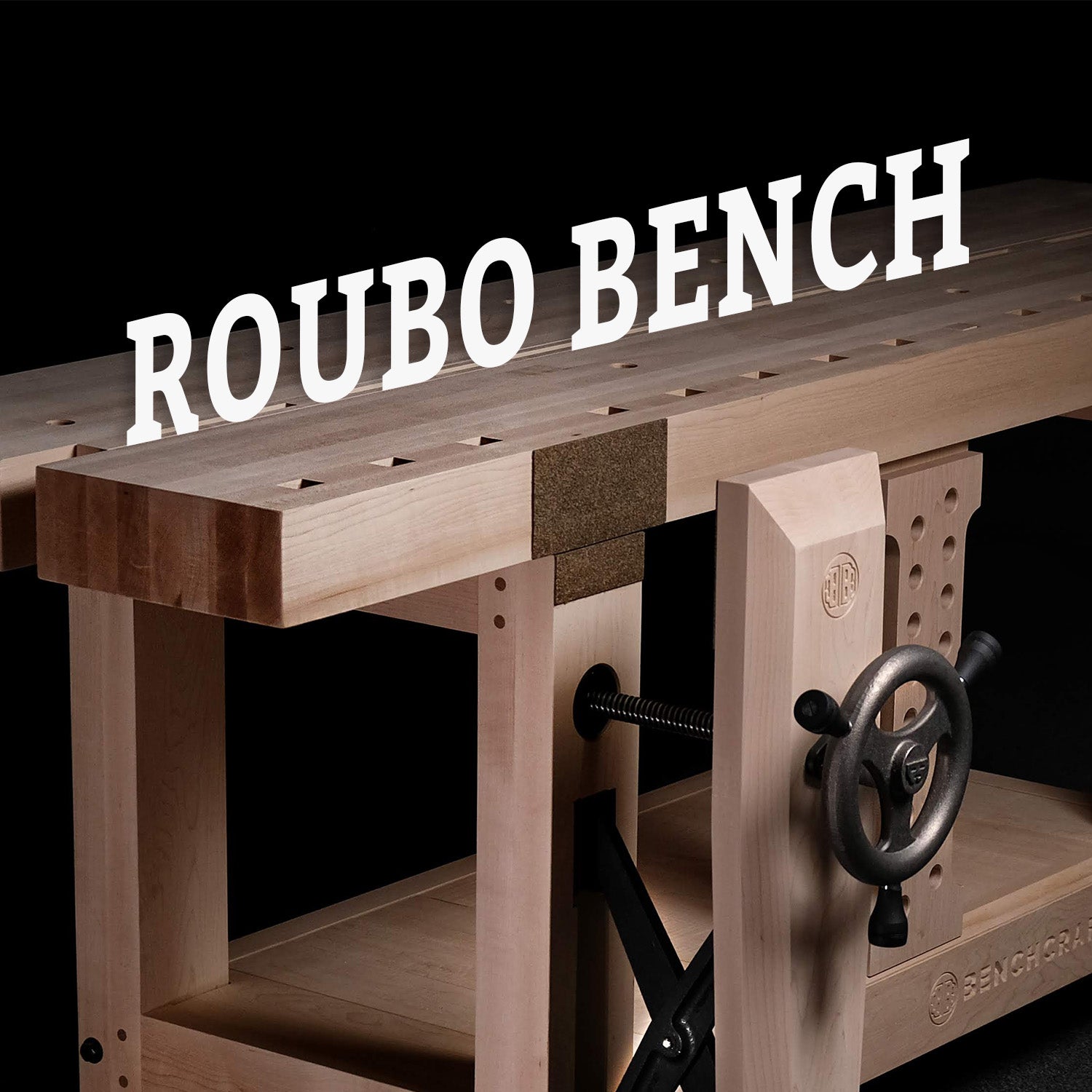

Can I install the vises in a bench other than a Roubo-style?

Sure. The tail vise will fit in any top. You'll need to add an end cap and possibly a dog hole strip. If you're replacing a traditional tail vise with a Benchcrafted, read more here. The Leg vise needs a leg flush with the front of your top to work to maximum capacity, but will work with a recessed leg. Write to us if you have questions.

Do you have any videos showing how to install the Vise?

Our European dealer Dieter Schmid Fine Tools has prepared this basic video showing how to install the Glide Leg Vise. It also covers the installation of the Crisscross Solo and Retro, and the same installation process applies to the Classic Leg Vise as well.

Classic Leg & Tail Vise

My vise parts are a dull black/gray and have some marks on them. Is this right?

The parkerized finish may arrive with a dull grayish cast. This is normal. There may also be some white marks that look like scratches on the parts. This is from handling the parts when we package them. The surface is sandblasted and easily takes light scuff marks.This is normal, and intended. The look of the vise is intended to reflect a vintage, patinated aesthetic, so feel free to leave it as is when you unpack it. The vise pictured above (and elsewhere on our site) was rubbed down with 0000 steel wool and lightly oiled, as per the instructions on page 11 of the Classic Leg vise Installation Instructions. As you use and handle the vise, it will develop a patina of its own. As with any steel part, you will want to protect it from rusting with a light oil. The parkerizing helps, but a thin coat of oil is part of the finish, and will need to be refreshed periodically. If you use the vise frequently, your natural hand oils should be sufficient. You can also apply a drying oil to the exposed areas of the parkerized parts (do not apply any drying finish to the dished part of the flange or hub.) We recommend Tru-Oil. Whatever you apply to the sliding handle will eventually wear off with normal use, including the parkerized finish. We designed the finish so it will rapidly develop a vintage, classic look.

Tail Vise

Can I install it on either end of my bench? Is the vise handed?

The Tail Vise is universal and can be configured for left-end or right-end use by simply assembling the sliding plate and nut accordingly. It's covered in the Tail Vise Installation Instructions.

See this video for assembly.

Why "tail" vise, I thought this was called a wagon vise?

The Benchcrafted Tail Vise is indeed a wagon vise, meaning it uses a traveling dog block trapped within the top. The term wagon vise did not derive from our use of a handwheel, as in “wagon wheel” but rather as a translation of the French term describing this general style of vise. It is also a "tail" vise since it’s mounted on the "tail end" of the bench. Others call it an "end vise". Hey, we had to pick something!

Round dogs or square?

We like square, but that's an old debate. Read our testimony here.

I have an early version of the Tail Vise with the curved nut block, can I still get the instructions and templates?

Email us and we'll send them to you.

Can I install the vise in a thinner or thicker top?

Yes and yes. You can install the vise in a top less than 3-¾” thick by shimming the rails or in a top thicker than 4”, by recessing them deeper. You'll also need to have a minimum 4" thick end cap to mount the vise flange. This is covered in the installation instructions. Read more

How long are the guide rails, and how much overhang do I need to accommodate the vise?

The rails are 18" long. Make your overhang at least 18 1/2" (including end cap) so that last half inch covers the end of the rails. That last half inch is an aesthetic touch, not functionally necessary.

How long is the screw past the flange?

The screw threads are 16" (nominal) past the inside of the flange.

How do I make square dog holes in my existing bench top?

You don't make the holes. They are created during the bench building process. Square dog holes are actually angled dadoes with a step and are milled into the edge of the top or dog hole laminate during construction. Read more

We also have a video on Routing Dog Holes

What glue should I use to attach the Crubber (or suede leather) to the vise jaws?

Any glue will work. But we like to use a water-based contact cement (solvent based is fine too, but it gives us a headache). Read more

Should I counterbore (recess) the flange bolt nuts on the inside of the end cap?

You can, but it makes installation much more finicky. We don't bother, since the chances that you'll ever need to open the vise that extra bit are pretty much zero.

Do you have any videos showing how to assemble the Tail Vise?

Yes. You can view it here.

Do you have any videos showing how to install the Tail Vise?

Our European dealer Dieter Schmid Fine Tools has prepared this basic video showing how to install the Tail Vise

What size should I make my dogs?

Dimensions are provided in the Tail Vise installation instructions.

Crisscross

I have an older Glide Leg Vise with a wooden parallel guide in the chop, can I install the Crisscross with it?

Yes. The Crisscross can work with any leg vise. You will likely need to make a new, longer chop to house the Crisscross. You will also need to modify your acetal bushing. Read more.

See this video for how to retrofit an original Glide with a Crisscross Retro.

I'm installing a Crisscross into an assembled bench, how do I route the mortises in the bench leg?

We like to flip the bench on the its back to do the install. See this video for more.

The pins fit tightly in the holes in my Crisscross, is this normal?

Yes. The black coating may get into some of the holes to more or less of a degree, this is normal. We like to leave the finish intact as much as possible between our shop and your shop. If your pins are tight or won’t enter, simply run a 3/8" drill bit through the holes (hold the part in a vise, not your hand) to clear away any excess finish.

Should I buy a Solo or a Retro?

Solos work best if you can drill the holes in the leg and chop for the mounting pins on a drill press, and that means getting your bench leg onto the press table. This is impossible on a completed bench. In this case, buy the Retro. Instead of drilling holes for mounting pins you'll fit Retro brackets inside the leg and chop mortise. You can of course use a Retro on a new bench if you'd rather install the brackets instead of the mounting pins. We recommend the Solo for new benches because its quicker and less expensive to install than the Retro.

After installing the Crisscross, the chop meets the leg at the top of the bench, but there is a gap between the chop and the leg towards the bottom. What's wrong?

This is called toe-in, and is purposely built into the vise. It's a sign that you've installed the Crisscross correctly. Toe-in ensures that the vise closes first at the top. This allows the vise to hold firmly. The gap at the bottom can be about 1/8"-1/2" depending on your chop height and how you installed the Crisscross. The distance is not important as long as your vise works properly and holds well. See the installation instructions for more details. Read more here.

I'd like to install the Crisscross on a Moravian-style bench, or an English-style Nicholson bench. Will the Crisscross work if I install it at an angle?

Yes. We tested the Crisscross during development on a bench with an angled leg vise. You can tilt up to 15 degrees, but beyond that you lose more of the weight-supporting function of the Crisscross, so the vise won't open and close as effortlessly as in a vertical installation. The further you tilt off vertical, the more weight is placed on the screw, and the more friction you'll get. On a similar topic, angled leg vises offer better holding for working the ends of wider boards (as in dovetailing), but we think a Moxon vise does this infinitely better than a leg vise, so we never bothered developing bench designs with angled leg vises.

I already cut my Crisscross mortises for 19" Crisscross arms, but I received the shorter 17-1/2" arms. What should I do?

First off, the 17-1/2" Crisscross arms will install just fine into the too-long mortise you cut. Your mortise will simply be a bit long at the bottom. There will be a 1-1/2" space below the Crisscross arms when the vise is completely closed (and thus, not seen). As soon as you open the vise the arms will start to "rise up" and there will be a gap down there anyway. It's just a visual thing, and doesn't affect the function of the Crisscross at all. You can mount the bearing plates at the very bottom of the mortise and the arms will still rub on the plates with the vise fully open. If the extra space at the bottom of the mortise bothers you, you can cut a block of wood and "fill in" the bottom 1-1/2" of your mortise in the leg and chop. If you're careful with grain selection it will be all but invisible.

STR S4S Kit

Do you offer replacement parts for the kits in case I ruin or lose a component?

We don’t offer replacement components. If you should ruin a component you’ll need to remake it in your shop. Hard maple is widely available.

What if I get my kit and there’s a missing component?

We allow 48 hrs to check your kit and claim any missing components. If you have missing components, write to us at info@benchcrafted.com and we’ll take care of you.

Can I get different species mixed in with my kit? Like a walnut end cap?

No, the kits are only offered in hard maple.

STR Plans

What's the total cost to build the bench?

In addition to the Benchmaker's package cost, your total will depend on the price of your lumber and how much waste you end up with after the building process. Lumber prices vary widely, so you’ll have to do some math along with a little guessing to arrive at a figure.

How much lumber do I need to buy to build the Split Top Roubo?

The finished bench itself uses just under 100 board feet. We usually purchase about 150 board feet of 8/4 stock if we can select each board carefully. Some lumber yards won't let you do that. In that case we order 200 board feet and use the surplus for shop projects. Read more

I don't like the split top. I'd rather have a solid, one-piece top, can I do it?

Of course. Just ignore the rear top section and build a full-width front section. Simple as that.

What species should I build it out of?

Short answer? Whatever you want. There are pluses and minuses to any species. We like soft maple as a generally available choice with good durability and workability. Ash, hard maple, southern yellow pine, beech, all good choices. Don’t use soft woods like fir or white pine.

What's the large hole at the top of the right leg for?

It's an access hole. You insert a finger to push up the dog directly above it.

Why no cut list?

Because they can introduce errors by promoting complacency. Blindly cutting parts without a firm grasp of what the part is and what its function is means you're not really building the bench, but trying to make a kit of parts that will hopefully fit together. It's much better to analyze each stage of construction and understand what the parts are before committing valuable stock. Cut lists are fine, as long as you make one up yourself from the plans.

Can I make the bench shorter than 87"?

Yes. Just make sure you alter your dimensions properly. You'll need to make the long rails shorter, and this will affect the dog hole spacing. You can also reduce the overhang at the left end of the bench to keep a wider footprint for the base. Don't change the overhang at the Tail Vise end. To add stability on this end (if you drastically shorten the bench) you can offset the right rear leg so its closer to the end of the bench. You'll need to make angled stretchers on the right end assembly. Best way to make the changes is to make a full-size story stick or drawing with the new dimensions right on it. Then you can refer to this in real time when building the bench. Read more.

My parallel-head clamps don't fit between the tops, how did that happen?

We built the prototype Split Top Roubo with the original Bessey K-body clamps in mind. The later ones (and other brands) are wider. You should build your bench to fit the clamps you have. If you already built your bench and the gap is too narrow and you'd like to make it wider, simply run the front edge of the rear top section over your jointer until your gap is wide enough.

How long will it take to build it?

From the time you start, until the time you finish. Seriously though, everyone works at a different pace and with different equipment. Take your time, enjoy the process and you'll be rewarded with a lifetime bench. In our shop, working 8 hour days with a well-equipped shop and our experience, we can build the Split Top Roubo in 5 days.

Your bench just looks like a Roubo bench with a couple extra features, why the special plans?

We wanted our vise customers to be able to build an excellent bench using our vises, without having to adapt them to others' plans. Benchcrafted vises were designed on a Roubo style bench, so it makes sense that we would offer a Roubo-style around our vises.

Mag-Blok

What surfaces can I mount my Mag-Blok to?

Mag-Bloks should ideally be mounted into a stud or solid surface. When mounting to drywall with no stud available you must use drywall anchors. We like the E-Z Anchor style.

Mounting to ceramic or stone surfaces can be done a few different ways. You can, of course use anchors again. If you'd prefer not to drill, though we don't officially endorse it, some of our customers have had good results using 3M VHB (Very High Bond) mounting tape (other brands have similar products). We cannot, however, vouch for its use. Do so at your own risk.

Will the Mag-Blok stick to my metal refrigerator?

No. The back side of the Mag-Blok does not have enough magnetism to hold it to a metal surface. If you'd like to adhere the Mag-Blok to the side of your refrigerator, though we don't officially endorse it, some of our customers have had good results using 3M VHB (Very High Bond) mounting tape (other brands have similar products). We cannot, however, vouch for its use. Do so at your own risk. You should never adhere your Mag-Blok to a moving object such as a refrigerator or cabinet door.

Can I mount the Mag-Blok vertically?

No. Due to magnetic polarity and other factors, we don't recommend it.

How much weight will they hold?

It depends on the object. Thicker, wider objects like cleavers will hold incredibly well. Thinner, rounder objects, like a sharpening steel won't hold as well. We engineered the Mag-Blok to hold a wide variety of knives and tools. Experiment, but be safe. The Mag-Blok was designed for small hand tools and kitchen knives.

How do you get the magnets in there?!

We started growing the trees for Mag-Bloks about 30 years ago, training the saplings to grow precisely around the magnets. Just kidding. If we told you, we'd have to, um, you know the rest.

Why does my cherry Mag-Blok appear lighter than the one pictured?

Cherry is a wood species that darkens rapidly with exposure to UV light. A freshly planed cherry board will darken noticeably within a day or two when exposed to sun. The Blok-Butter will also darken the cherry when you apply it. Depending on where you mount your cherry Mag-Blok and how much sun it sees, you can expect your cherry Mag-Blok to darken after a few weeks of taking it out of the package. You can accelerate this process by placing the Mag-Blok on a window sill for a few days. You may also notice light and dark areas of the cherry as it ages since the knives slow the darkening process in the areas where they are mounted to the Mag-Blok. This will even out over time depending on your usage and light situation.

Why are there dark stains on the face of my Mag-Blok?

If your knives are made from high carbon steel and you put the knife away with moisture still on the blade, you'll get dark stains on the wood from the steel reacting with the trapped moisture. This is especially true with white oak, which contains more tannins than our other species. Make sure you dry your knives completely before putting them back on your Mag-Blok. To remove the stains, block sand the face of the Mag-Blok with 150 grit sandpaper until the stains are gone. Further smooth the surface with 180 and 220 grit sandpaper, then apply a fresh coat of Blok-Butter.

My knife won't stick!

It's probably made from stainless steel. Think about getting some better quality knives with more carbon content. Carbon means quality-- edge retention and fine grain for a keen edge. Many of our dealers will be quite eager to sell you an excellent knife. A knife that may well amaze you.

Will you make a Mag-Blok from my piece of wood?

Sorry, not at this time.